skpharmaequipment@gmail.com - GST NO. : 24CAVPS2797B1Z6

- Send Email

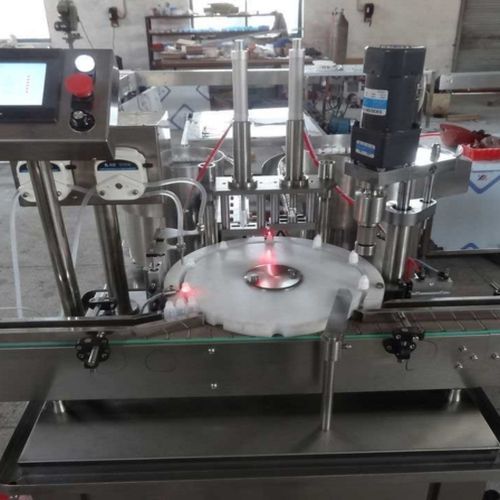

Packaging Machine

Leading Manufacturers, Wholesaler, Exporters, Retailer of Bottle Filling Machine, Homogenizer Tank, Liquid Filling Machine, Powder Filling Machine and Sticker Labeling Machine from Ahmedabad.

| Business Type | Manufacturer, Supplier |

| Driven Type | Electric |

| Color | Grey |

| Automatic Grade | Automatic |

| Power | 1-3kw |

| Application | Industrial |

| Voltage | 320 V |

| Warranty | 1year |

| Country of Origin | India |

Key Features

1. High Accuracy: Precise filling volumes ensure consistent product quality.

2. Adjustable Filling Volumes: Easily adjustable to accommodate different bottle sizes and fill volumes.

3. Automatic Operation: Minimizes manual labor and increases production efficiency.

4. Quick Changeovers: Designed for easy changeovers between different bottle sizes and types.

5. Sanitary Design: Easy to clean and sanitize, ensuring compliance with industry regulations.

Benefits

1. Increased Productivity: Automates the filling process, reducing labor costs and increasing production rates.

2. Improved Accuracy: Precise filling volumes reduce waste and ensure consistent product quality.

3. Reduced Labor Costs: Minimizes manual labor, freeing up staff for other tasks.

4. Flexibility: Can handle various bottle sizes, shapes, and materials.

Applications

1. Food and Beverage: Filling bottles with water, juice, soda, oil, and other liquids.

2. Pharmaceuticals: Filling bottles with medicines, vaccines, and other pharmaceutical products.

3. Cosmetics: Filling bottles with shampoos, conditioners, lotions, and other personal care products.

4. Chemical: Filling bottles with cleaning products, lubricants, and other chemicals.

Types of Automatic Bottle Filling Machines

1. Piston Filling Machines: Use a piston to accurately measure and dispense liquids.

2. Gravity Filling Machines: Use gravity to fill bottles, suitable for low-viscosity liquids.

3. Vacuum Filling Machines: Use vacuum pressure to fill bottles, ideal for filling bottles with precise amounts.

Specifications

1. Filling Capacity: Ranges from a few bottles per minute to hundreds of bottles per minute.

2. Filling Volume: Adjustable filling volumes, typically ranging from a few milliliters to several liters.

3. Bottle Size Range: Accommodates various bottle sizes, from small to large.

When selecting an automatic bottle filling machine, consider factors like production capacity, filling accuracy, and compatibility with your product and packaging.

| Business Type | Manufacturer, Supplier |

| Surface Finishing | Polished |

| Shape | Round |

| Color | Metallic |

| Application | Storage Use |

| Capacity | 1000-5000L |

| Country of Origin | India |

The Homogenizer Tank is engineered for high-efficiency blending and emulsification, providing consistent and uniform mixing of liquids and semi-solids. Ideal for applications in the pharmaceutical, food and beverage, cosmetics, and chemical industries, this tank ensures that all components are evenly dispersed, resulting in a homogeneous product. Featuring robust construction, advanced mixing technology, and customization options, the Homogenizer Tank is designed to meet the specific needs of various industrial processes.

High-Efficiency Homogenization

Equipped with advanced homogenizer mechanisms, including high-shear mixers or ultrasonic homogenizers, the tank ensures thorough mixing and breaks down particles for uniform consistency, even in challenging formulations.

Durable and Corrosion-Resistant Construction

Built from materials such as stainless steel or corrosion-resistant alloys, the tank offers long-lasting performance and reliability. Suitable for handling a wide range of products, from aggressive chemicals to delicate food ingredients.

Temperature Control Options

Optional heating or cooling jackets and insulation are available to maintain optimal processing temperatures, making the tank suitable for heat-sensitive materials or processes that require precise temperature management.

| Business Type | Manufacturer, Supplier |

| Finishing | Polished |

| Driven Type | Electric |

| Operating Type | Automatic |

| Usage | Industrial |

| Voltage | 380V |

| Phase | Single Phase |

| Warranty | 1 Year |

| Country of Origin | India |

A Liquid Filling Machine is an essential piece of equipment designed to automate the process of filling liquid products into various containers, such as bottles, jars, pouches, and cans. This machine is utilized across a wide range of industries, including food and beverage, pharmaceuticals, cosmetics, and chemicals, to enhance efficiency, ensure precise filling, and maintain product integrity. With state-of-the-art technology and customizable features, liquid filling machines cater to diverse liquid packaging needs.

High Precision Filling

Liquid Filling Machines are equipped with advanced metering and filling systems that guarantee accurate volume dispensing, minimizing waste and ensuring consistency across every container.

Versatile Handling

Capable of filling a wide variety of liquids, including water, oils, juices, sauces, chemicals, and creams, making them suitable for diverse applications and industries.

High-Speed Operation

Designed for efficiency, these machines can fill multiple containers per minute, significantly increasing production rates and effectively meeting high demand.

| Business Type | Manufacturer, Supplier |

| Finishing | Polished |

| Driven Type | Electric |

| Color | Grey |

| Automatic Grade | Automatic |

| Certification | CE Certified |

| Voltage | 220V |

| Phase | Single Phase |

| Warranty | 1 Year |

| Country of Origin | India |

A Powder Filling Machine is a specialized equipment designed for the automatic filling of various powdered products into containers, bags, or pouches. Widely used across industries such as food, pharmaceuticals, cosmetics, and chemicals, this machine ensures accurate dosing and efficient packaging, enhancing productivity and product quality. With advanced technology and customizable features, powder filling machines cater to diverse packaging needs.

High Accuracy and Consistency

Equipped with advanced weighing and filling technology, the Powder Filling Machine ensures precise measurement and consistent filling of powders, minimizing waste and ensuring uniformity in each package.

Versatile Filling Options

Designed to handle a wide range of powder types, including fine powders, granules, and coarse materials, making it suitable for various applications across different industries.

High-Speed Operation

Capable of filling multiple containers or pouches per minute, significantly increasing production rates and meeting high demand in manufacturing environments.

| Business Type | Manufacturer, Supplier |

| Driven Type | Electric |

| Color | Grey |

| Automatic Grade | Automatic |

| Pressure | High Pressure |

| Certification | CE Certified |

| Voltage | 380V |

| Warranty | 1year |

| Country of Origin | India |

A Sticker Labeling Machine is an essential piece of equipment used in various industries to apply labels accurately and efficiently to products. This machine is designed to handle a wide range of container shapes and sizes, including bottles, jars, boxes, and pouches. With its advanced technology and customizable features, a sticker labeling machine enhances the productivity of packaging lines while ensuring that every label is applied perfectly.

High Accuracy

Equipped with precise labeling mechanisms, the Sticker Labeling Machine ensures accurate label placement, reducing mislabeling and enhancing product presentation.

Versatile Labeling Options

Capable of applying various types of labels, including pressure-sensitive, adhesive, and heat shrink labels, making it suitable for a wide array of products across different industries.

Durable Construction

Made from high-quality materials, the machine is built to withstand continuous use in demanding production environments, ensuring longevity and reliability.